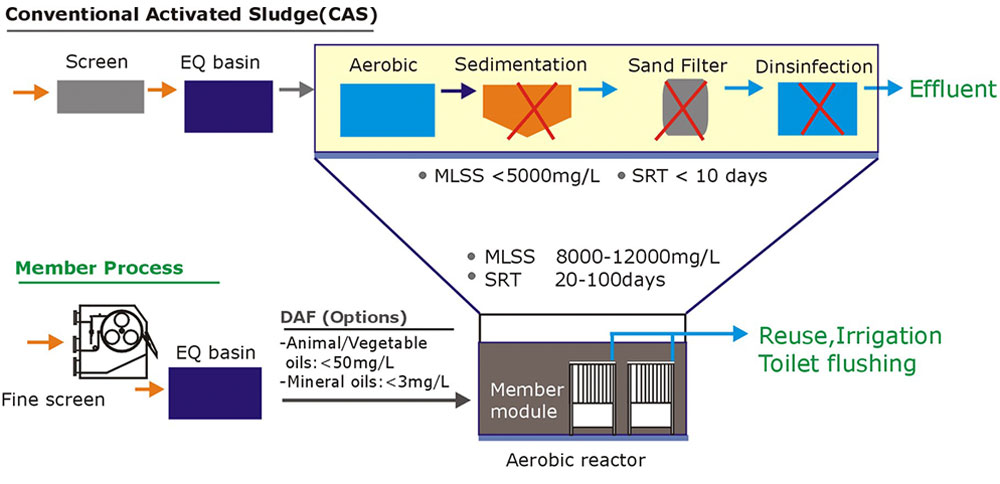

Ecologix™ MBR module systems replace the Clarifier, Sand filter and Disinfection processes used in Conventional Activated Sludge (CAS) process by removing the suspended materials with Ultra-Filtration membrane. The membranes modules are submerged in a biological tank or side streams tank, with the water being drawn through the membranes under vacuum, leaving the suspended biomass material in the biological aeration tank. The MBR systems have a smaller footprint than CAS systems, produce consistent effluent quality even in varying influent conditions, and provide effective treatment for high BOD levels in wastewater.

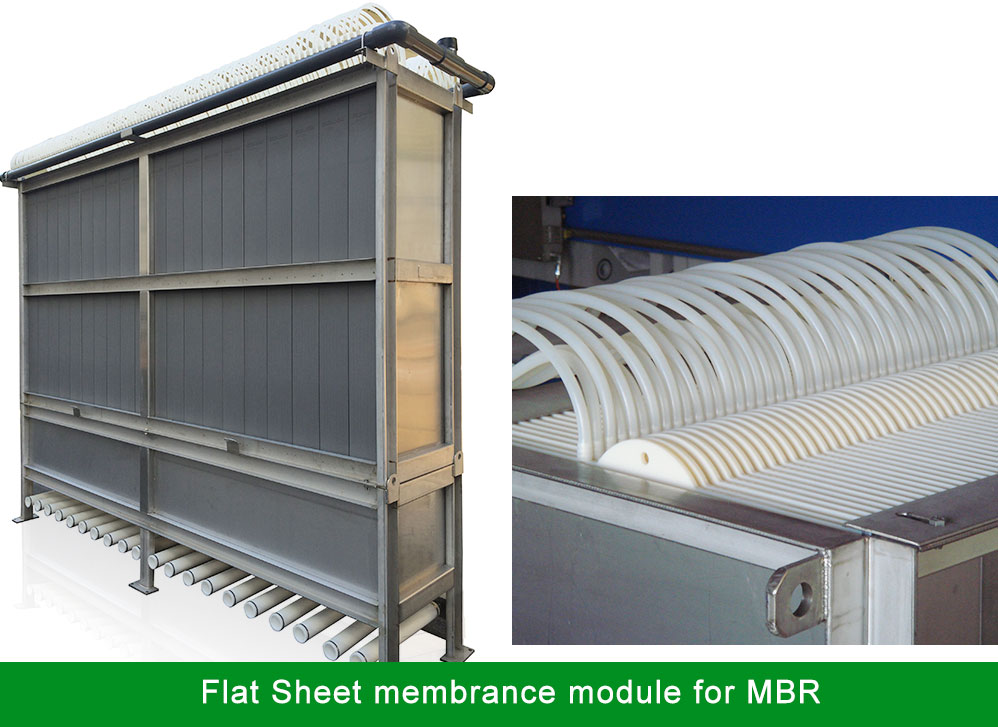

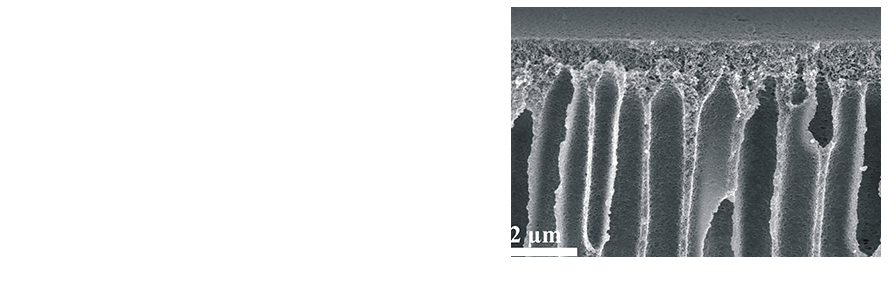

Ecologix group signed a contract, use Microdyn-Nadir PVDF and PES Asymmetric membrane for all of EcoPlate flat sheet membrane element, and achieve the membrane module –

● Increase performance (higher flux)

● Longevity and Significantly

● reduce foulingtendency

Ecologix Asia: Leading manufacture the MBR module - cooperation with Germany and Japan

Microdyn-Nadir Membrane

Membrane plate welding

Membrane plate

Module assembly

Membrane Module

Prepare shipment

The best membrane material, precision welding technology, lower assembly costs in Taiwan and included special designed air block, EcoPlate MBR module become to be the high quality and best price in the market.

As of 2015, over 115 Ecologix MBR systems in operation around the world challenged with a variety of different municipal and industrial wastewaters, included 200-500m3/d of municipal and hospital, 1,500m3/d of landfill leachate, 4,800m3/d of petrochemical effluent.

Ecologix™ MBR module systems replace the Clarifier, Sand filter and Disinfection processes used in Conventional Activated Sludge (CAS) process by removing the suspended materials with Ultra-Filtration membrane. The membranes modules are submerged in a biological tank or side streams tank, with the water being drawn through the membranes under vacuum, leaving the suspended biomass material in the biological aeration tank. The MBR systems have a smaller footprint than CAS systems, produce consistent effluent quality even in varying influent conditions, and provide effective treatment for high BOD levels in wastewater.

© 2022 Ecologix. All rights reserved - Developed by David Lo.